Polyester and nylon filament yarns are typically used to manufacture belting fabrics. These belting fabrics are utilized in numerous industries like mining, automotive, and construction. They have superior adhesion and high tensile strength for use in industries that require the transportation of large quantities of materials.

So, belting fabrics are usually utilized for manufacturing automotive and conveyor belts that exhibit certain characteristics. These features include high-dimensional stability, abrasion and moisture resistance, low elongation, high durability, optimal strain stress level, and more

Types of Belting Fabrics

You must understand different types of essential belting fabrics before using them in automotive and conveyor belts production.

R-Fabric

This is a rigid type of fabric that gives the belt good strength and stability. R-fabrics are made of monofilament yarns, which are available in different types. The rigidity of R-fabric is determined by the type of monofilament yarn used for manufacturing.

N-Fabric

These are non-rigid fabrics with flexibility in length and width. Therefore, N-fabric yarns become suitable for bulk transport and curved belts.

DRA-Fabric

It is characterized as a special fabric used for conveyor belts and is an interwoven polyester fabric.

RZ-Fabric

This type of fabric is manufactured by combining monofilament yarn and viscose yarn for use in bakeries.

CP-Fabric

A combination of cotton and polyester fabric forms the CP-fabric. This is a fabric with cotton absorbing moisture and polyester providing strength to the belts.

W-Fabric

They are known as whisper fabric as they produce little to no noise when used. These W-fabrics are an excellent fit for sites with a considerable people, such as terminals or gyms.

M-Fabric

These fabrics are created from monofilament yarns and display improved stability. They are utilized in heavy-duty assignments in industries such as mining and construction.

Key Properties of Belting Fabrics

Belting fabrics are engineered with different properties to ensure long life and efficient operation. These properties include:

High Tensile Strength

Belting fabrics handle heavy loads and tension without tearing.

Low Elongation

These fabrics ensure consistent belt tracking and minimal slippage.

Flexibility

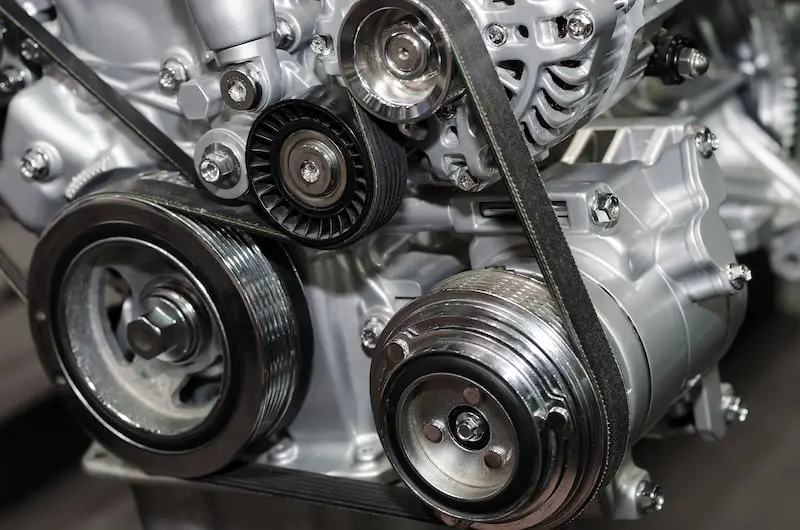

They allow the belt to move over pulleys and rollers without cracking.

Abrasion Resistance

Belting fabrics can withstand rough materials and environments.

Heat and Chemical Resistance

These features are available in specialized belts for high-temperature or corrosive settings.

Use of Belting Fabrics

The applications of belting fabrics are seen in various industries and domains, with general-purpose belts and application-specific belts. This segregation defines the construction and materials utilized in fabricating these belts.

Automotive

Belting fabrics are used in automotive companies for seatbelts in cars or other vehicles.

Construction

Construction companies use heavy-duty belts for construction equipment and materials. Heat-resistant belting fabrics with reinforced layers for durability resist dust, heat, and abrasion.

Manufacturing

This domain uses conveyor belts to enable a seamless sliding of materials during the production process, used to transfer packages toward an elevated region.

Rubber and Tire Industry

Belting fabrics are used as reinforcement materials in the production of various rubber products, including high-performance tyres and diaphragms.

Textile Industry

Belting fabrics are used in spinning, weaving, and dyeing units. They are utilized in conveyor belts for fabric movement and timing belts in textile machinery.

Mining Industry

To move raw materials like coal, ore, and stone, mining operations use strong conveyor belts. Belting fabrics used here must withstand high impact from falling materials, abrasive particles, and heavy loads over long distances.

Conclusion

Fabrics from Shree Ganesh Enterprises for the belting industry have efficient performance that determines the efficiency, safety, and productivity of countless

industrial systems. Your choice of selecting these fabrics from our team will directly impact the durability, cost-effectiveness, and operational success of your industry.